- Mud Pump Cylinder Liner

- Mud Pump Valve Assembly

- Mud Pump Piston

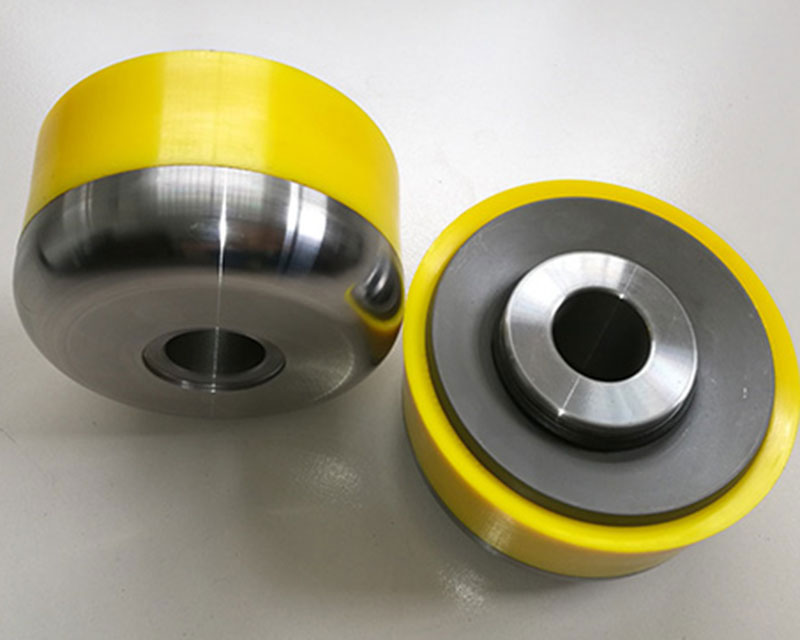

Mud Pump Piston

Piston

- Type:Mud Pump Piston

- Code:

-

In the oil drilling industry, Piston plays a vital role as one of the core components of the hydraulic end of the drilling pump. It not only directly affects the pumping efficiency, but also relates to the reliability and service life of the equipment. The following is a product introduction to this key part of the piston.

Piston is an important part of the hydraulic end of an oil drilling pump and is primarily used to convert externally supplied mechanical energy into power for transporting fluids. In high pressure environments, the piston needs to continue to withstand huge pressure, and maintain a stable working state in high-speed reciprocating motion. To this end, the design and manufacture of products must meet the requirements of high strength, high wear resistance and high sealing.

- Product Description

Product Description

In the oil drilling industry, Piston plays a vital role as one of the core components of the hydraulic end of the drilling pump. It not only directly affects the pumping efficiency, but also relates to the reliability and service life of the equipment. The following is a product introduction to this key part of the piston.

Product overview

Piston is an important part of the hydraulic end of an oil drilling pump and is primarily used to convert externally supplied mechanical energy into power for transporting fluids. In high pressure environments, the piston needs to continue to withstand huge pressure, and maintain a stable working state in high-speed reciprocating motion. To this end, the design and manufacture of products must meet the requirements of high strength, high wear resistance and high sealing.

Main feature

High-strength materials: Made of high-strength alloy materials, such as high-strength steel or special alloys, to ensure that it can maintain good mechanical properties under extreme working conditions. These materials have excellent tensile strength and toughness and can withstand high pressure shocks and wear.

Precision machining: After precision machining, smooth surface, accurate size, to ensure a good fit with other components in the pump. This high precision machining helps to improve sealing and extend service life.

In oil drilling operations, the performance of Piston directly affects the overall performance of the drilling pump. A quality piston not only improves the efficiency of the drilling pump and reduces energy consumption, but also reduces maintenance costs by reducing the incidence of failure.

Product Pictures

Suitable Pump Models

|

Bomco |

F-500 |

F-800 |

F-1000 |

F-1300 |

F-1600 |

F-1600HL |

|

|

Emsco |

F-350 |

F-500 |

F-650 |

F-800 |

F-1000 |

FD-1000 |

FB-1300 |

|

FB-1600 |

FA-1600 |

FA-1300 |

FC-1600 |

FD-1600 |

FC-2200D-300/500 |

D-175 |

|

|

D-225 |

D-375 |

D-500 |

D-550 |

DA-500 |

DB-500 |

D-700 |

|

|

DA-70 |

DB-700 |

DC-700 |

DA-850 |

DB-850 |

DC-850 |

D-1000 |

|

|

DB-1000 |

DC-1000 |

D-1000-A |

D-1350 |

D-1650 |

|

|

|

|

National |

7-P-50 |

8-P-80 |

9-P-100 |

10-P-130 |

12-P-160 |

14-P-220 |

JWS-165-L |

|

JWS-340 |

JWS-400 |

C-250 |

C-350 |

K-380 |

K-500-A |

G-700 |

|

|

K-700 |

N-1000 |

N-1300 |

N-1600 |

|

|

|

|

|

Gardner Denver |

PZ-7 |

PZ-8 |

PZ-9 |

PZ-10 |

PZ-11 |

FK-FXK |

FY-FXD |

|

FD-FXX |

FG-GXG |

FG-FXG |

KG-KXG |

FQ-FXQ |

FF-FXF |

FF-FXP |

|

|

TGE |

TGF |

TGH |

PAH-275 |

|

|

|

|

|

Drillmec |

7TS-600 |

8T-800 |

9T1000 |

10T-1300 |

12T1600 |

14T-2200 |

10D2C |

|

8D1S |

|

|

|

|

|

|

|

|

Upetrom |

3PN-1000 |

3PN-1600 |

3PN-1300 |

3PN-2000 |

|

|

|

|

OPI |

350-D |

350-GD |

500-DC |

700-HDL |

1000-HDL |

|

|

|

American Block |

K800 |

K1000 |

K1300 |

K1600 |

K2200 |

|

|

|

Loadmaster |

LSF-500 |

LSF-800 |

LSF-1000 |

LSF-1300 |

LSF-1600 |

|

|

|

Soilmec |

7T500 |

7T508 |

8T650 |

|

|

|

|

|

Dragon |

440HP |

660HP |

|

|

|

|

|

|

GASO/Wheatly |

1550 |

1560 |

1563 |

1654 |

1742 |

1753 |

1874 |

|

1849 |

1860 |

2652 |

|

|

|

|

All conventional pump type accessories can be produced

Factory environment

Production equipment

Factory scene

-

Whatsapp/Tel: +86 18766752985+86 18315949254+86 18653487112

-

WeChat+86 18766752985+86 18315949254deng15092539254

-

Email: michael@dzlrtc.comcathy@dzlrtc.com

All rights reserved © Dezhou Lianrui Technology Co., LTD. 2024

Technical support:JISU